Our Services

Wire Processing

Automated Wire Processing Services

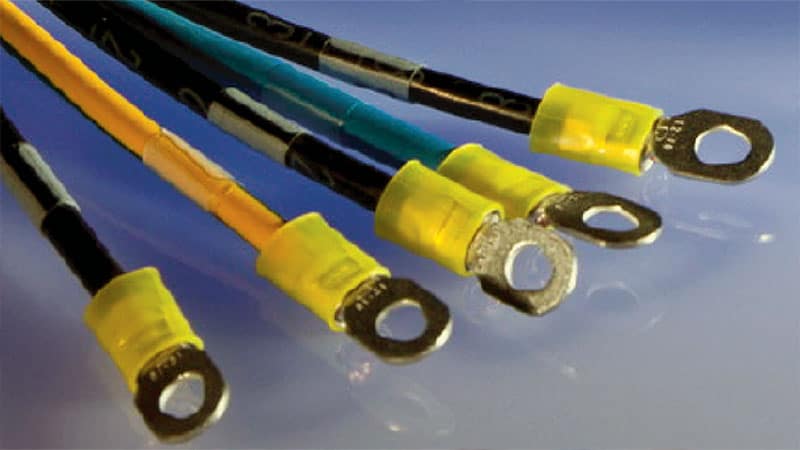

General Manufacturing has the capability to perform automated wire and cable processing by utilizing equipment and technology. Our fully automated machinery allows us to cut, strip, and terminate wires and cables in the most efficient and least costly way.

Our Wire Processing Equipment

General Manufacturing utilizes wire processing equipment from companies such as Komax, Schleuniger, Tyco(AMP), and Molex, to efficiently meet your wire and cable processing needs. We have the capabilities to crimp both ends of a wire, double crimp the connections with up to three different contacts, and carry out one-ended seal applications and tinning with label markings. I

In addition, our machines have process monitoring that is fully integrated while the product is being built. This allows us to cut and strip the wire as well as terminate it with the correct terminal exactly to your specifications. This optimizes quality control with crimp force monitoring, seal monitoring, splice monitoring, a detection system for wire end and knots, and comprehensive good/bad sorting of final products.

We also have cost-effective, fully automated crimping machines capable of twisting and tinning wires with a cross section from AWG 30-12 as well as twisting and tinning wire lengths from 2 to 25mm.

Our operators are able to perform a variety of processing options, including twisting/tinning, full tinning, or tip tinning. Our machines allow us to produce ideal twisting and tinning quality at minimal cost.

Wire Processing Automation Estimate

General Manufacturing Corporation has been servicing the Industrial, Robotics, Medical, Military and Automotive Industries since 1998. We specialize in prototype to production of electro-mechanical assemblies, wire harness assemblies, cable assemblies and processed wire.

If you’re interested in the benefits of wire processing automation, we are ready to help.